Horizontal double heads semi automatic pistion filling machine pneumatic liquid drink beverage filler dual nozzles filler for paste ketchup cream

Model:GR-F02-1000

Power supply:AC220V/110V 50/60Hz

Power:50W

Air pressure:0.4-0.6Mpa

Filling speed:10-50 bottles/min(can be adjusted 10-15 bottles/minute for one nozzle)

Filling accuracy:±1%

Material: 304 stainless steel or 316 stainless steel

Optional models:3-25ml,5-100ml,10-300ml,50-500ml,100-1000ml,500-2500ml,1000-5000ml

Dimension(L*W*H):900(L)x500(W)x200(H)MM

Weight:50kg

Semi-automatic: You can set the interval time to let it fill automatically or use the foot pedal to control each filling time

Application: liquid like oil, water, milk, drinks, honey, detergent, etc

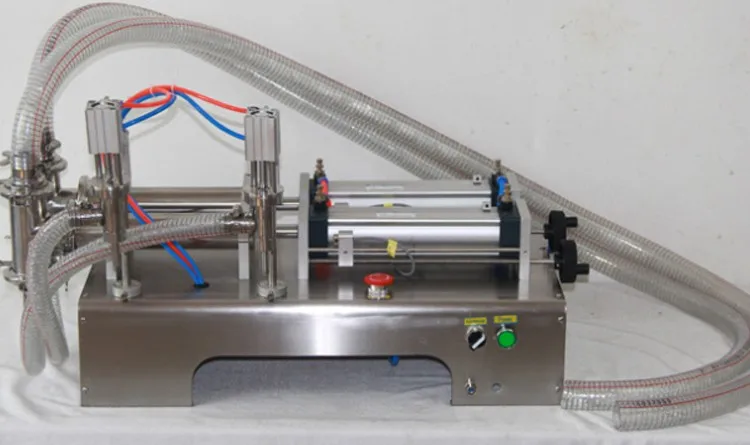

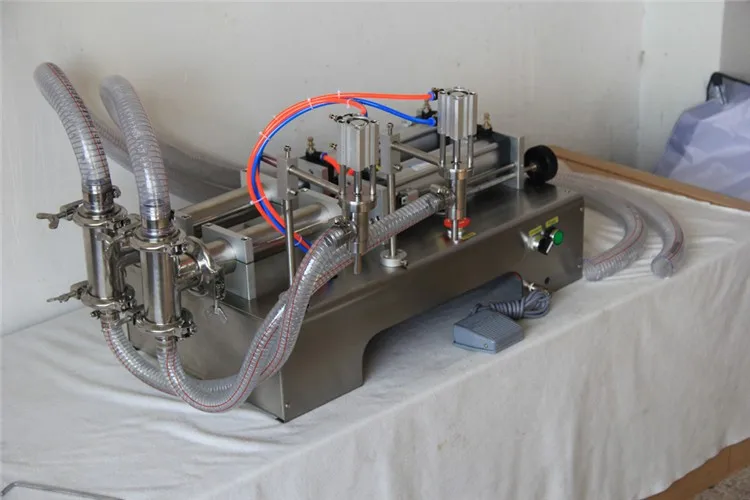

The Model GR-F02-1000 is a product innovated and upgraded on the basis of this company's series products and introduced foreign advanced filling machine technology. It has Two Heads and Two Valves, Each Head matchs own Valves, it can work Separately, makes the filling capacity very precise. And it is simple and reasonable in design, high in accuracy and easy in operation. Suitable for filling liquid in the industries of pharmaceutics, daily chemicals, , cosmetics,beverage, pesticide and special trades. The machine is safe and with the personalized design, can meet the modern enterprises' requirements. And the pneumatic part adopts the pneumatic components of Germany FESTO and Taiwan's AirTac. The part contacting materials is made of 316L stainless steel. With adjustment handle of filling volume, the filling speed can be adjusted at will, with high filling accuracy. Filling head adopts anti-leakage, anti-pull and with diving filling device.

Detailed Images

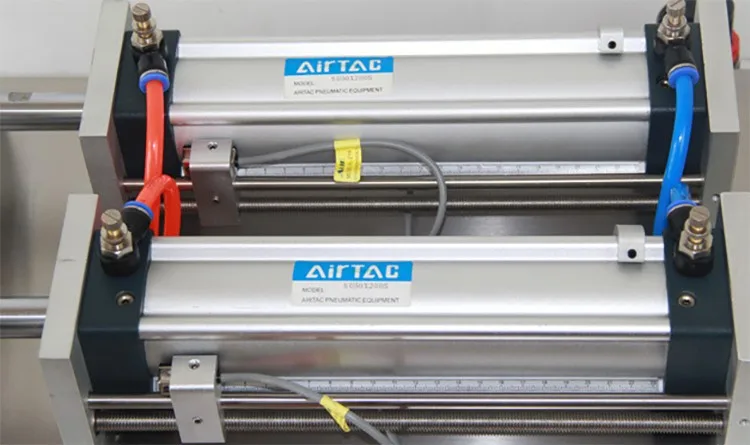

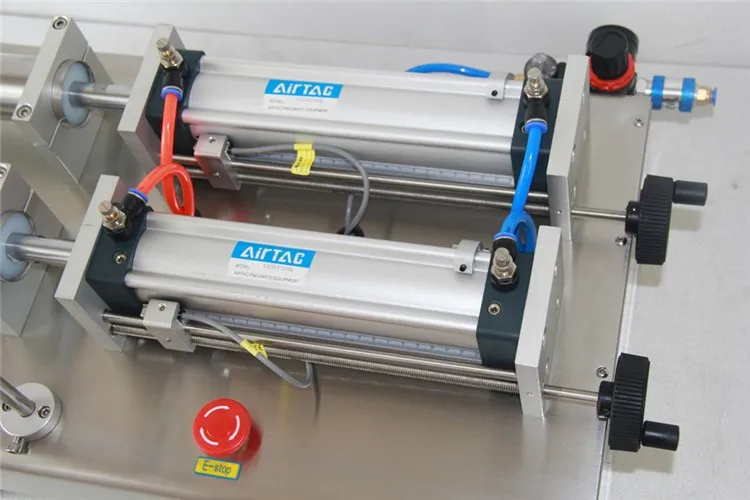

AirTAC plus large power cylinder

AirTAC high-power cylinders are more powerful, more efficient and more durable.

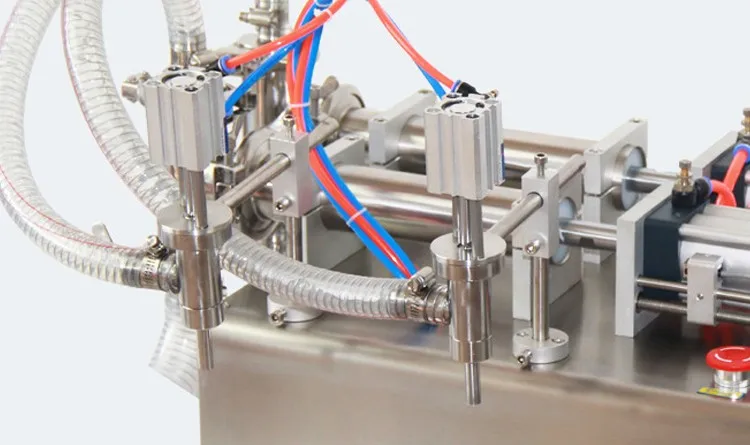

Simple filling nozzle design & Anti-drip design

Anti-drip, accurate filling, no clogging, detachable, easy to clean and maintain

Stainless steel body

The structure of the whole machine is reasonably selected and refined, and it will never be deformed.

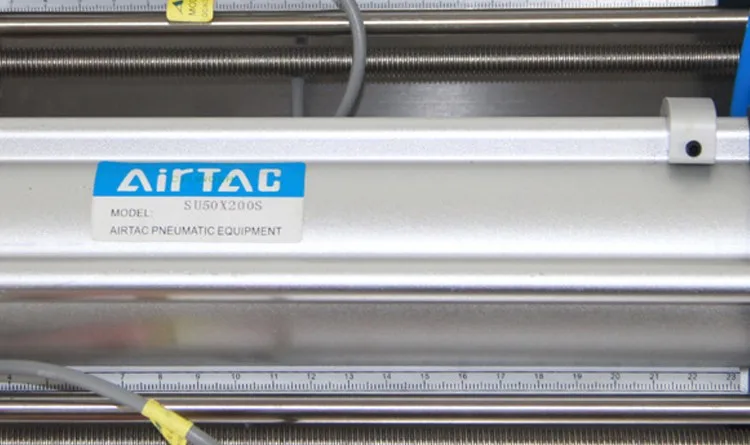

Filling scale

Precise, efficient and safe design

Adjusting the joystick

A hand crank that adjusts the filling amount can be adjusted in size and is easy to operate.

Emergency stop switch

Built-in safety power-off design protects the machine in time to prevent safety accidents.

High quality hose

High-quality feeding tube makes the machine discharge more smoothly and has a longer service life.

This filling machine can be used to fill beverages, wine, petroleum, daily chemicals, edible oils, medicines, pesticides and other liquids, suitable for corrosive liquids, acid and alkali resistant, and corrosion resistant. Suitable for small businesses as well as small shops.

Features And Advantages

1.This machine adopts imported mechanical parts, the pistons and cylinders are made of stainless steel and PTFE.

2. The imported components of excellent quality and outstanding mechanical design have ensured its absolute leading position among other same machines in the country.

3.The machine is light and convenient with brand new horizontal design and automatic material drawing, removing the trouble of frequent feeding of the vertical material hopper.

Operation steps:

Why Choose Fluid Power Systems over Electrical or Mechanical Systems?

Fluid power produces linear motion using pneumatic or hydraulic cylinders as opposed to electrical and mechanical methods. You don’t need electrical power for fluid power systems, eliminating the risk of shocks, fire, sparks or even explosions. They do not use electricity to operate, meaning a large and expensive explosion proof case is not needed.

Pneumatic systems will simply stall when broken instead of possibly exploding like electrical motors. Medical facilities also use pneumatics in place of hydraulics for the same reason as food manufacturers. They are much safer and cause almost no contamination if they break.

Pneumatics are also favored for their resistance to heat; electric motors are prone to overheating but with gas, pneumatic systems do not produce nearly as much heat due to the compressed air constantly carrying heat away.

Understanding the Difference Between Pneumatic and Hydraulic Systems

Hydraulic systems are typically preferred in heavy equipment and machines requiring major power transmission.

The important principles of pneumatics are essentially the same as hydraulic system, but there are several distinctions to keep in mind.

Pneumatics utilizes gas instead of liquid to transfer power

Because gas can be compressed, there is a delay in movement in pneumatic systems

Pneumatics generates higher energy costs due to energy lost from heat production during compression

Hydraulics handles greater force than pneumatics

Air is pumped into a receiver and compressed, ready to be used by the pneumatic system as needed. The air taken from the area around the compressor is filled with contaminants such as dirt, dust and water vapor. To combat this, strong filters are installed keep the air clean and dry.

Machine detail parts:

Workshop:

Other related filling machines according to different filling materials:

Packing & Delivery